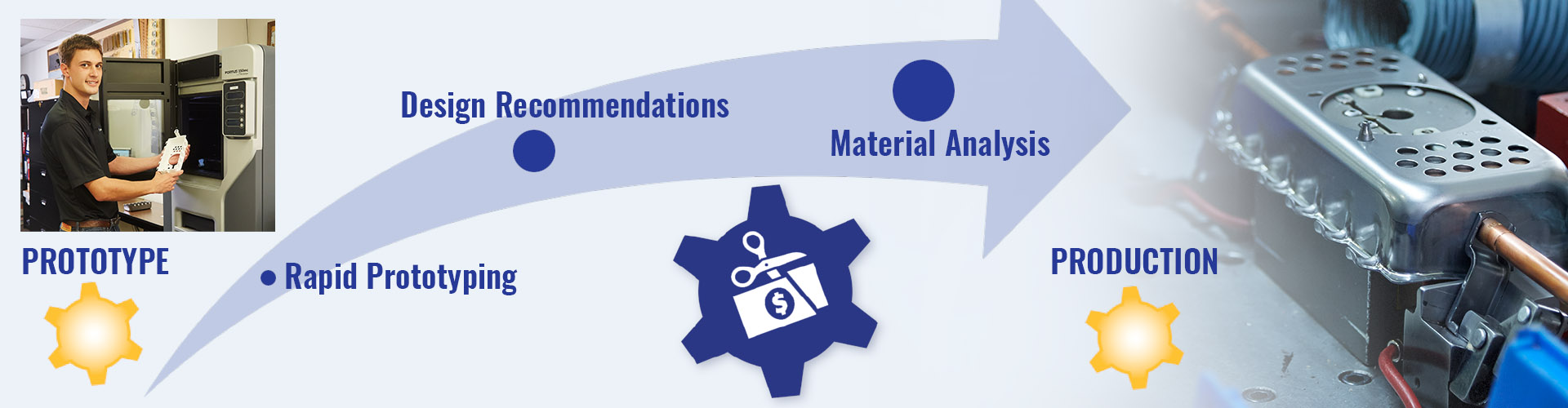

Prototype to Production

The quality and reliability of prototypes are critical to test and meet design requirements during new product development. IMS Buhrke-Olson has a dedicated prototype team and promotes early engineering involvement to provide design recommendations for improved manufacturability and cost improvements as well as advanced product and formability analysis.

- Dedicated prototype team and resources

- Early engineering involvement

- Design recommendations for improved manufacturability and cost improvements

- Advanced product and formability analysis

Prototypes

IMS Buhrke-Olson offers early engineering involvement to provide complete prototype sourcing supported by full CAD/CAM capabilities utilizing EDS Unigraphics™ , SolidWorks™, Pro/ENGINEER™ and AutoCAD™. For advanced product analysis, IMS Buhrke-Olson utilizes additional tools including strain form analysis, photolithography and FASTFORM Advanced.

Engineering

The IMS Buhrke-Olson staff of design, tooling, quality and project engineers consists of more than 30 experienced and professional technical individuals. Besides prototyping, engineering support includes tooling development, design, process design and production efficiency improvements throughout the product life cycle. IMS Buhrke-Olson uses an integrated CAD to CMM/DCC interface and internet file transfer capability for PRT, IGS, DXF, DWG, JPG and TIF file formats. Total early engineering involvement includes tool design and construction, comprehensive project management, value analysis/value engineering, die, fixture and special equipment design, reverse engineering and additional support in fabrication, machining and special applications engineering through the IMS Companies’ broad base and value-added engineering capabilities.